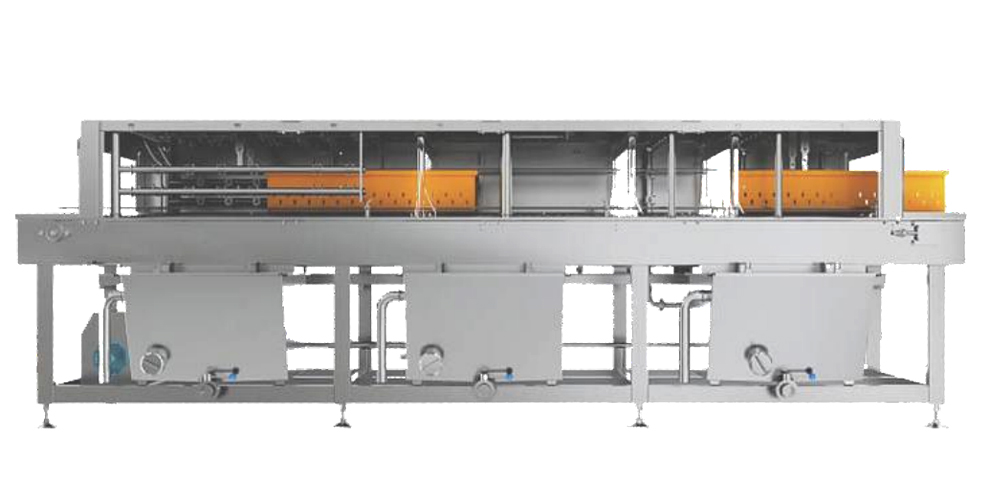

1. Floating plate cleaning machine

2. Description: the floating plate cleaning process includes high-pressure and high-temperature cleaning, physical dust removal of left and right wool slivers and upper and lower wool rollers, high-pressure hot water cleaning, high-pressure clean water cleaning, upper and lower wind knife water removal, ultraviolet sterilization and other six stages to ensure good cleaning effect. The whole equipment is 304 stainless steel, the power of drive motor is 0.75KW, the power of water pump is 4kw + 4kw + 3KW, the power of rough roller cleaning system is 0.55kw, the power of water removal fan is 2 sets, 0.75KW, the power of electric heating tube is 9kw X4 (single control), the transmission speed is 2-10M / min, the length of cleaning tunnel is 6.92m, the height of assembly line is 700-750mm, all motors are covered with covers to prevent water immersion.

Brand of ultraviolet lamp: Philips of the Netherlands, Heraeus of Germany, lightsources of the United States